Cutting

Posters, wrapping paper, business cards, leaflets, flyers, and more.

Leaflets

We are able to cut a wide variety of sizes, from standard A4/B5 sizes to unconventional ones. We are also able to add papers between stacks of leaflets to prevent smudging or add obi bands around stacks of them.

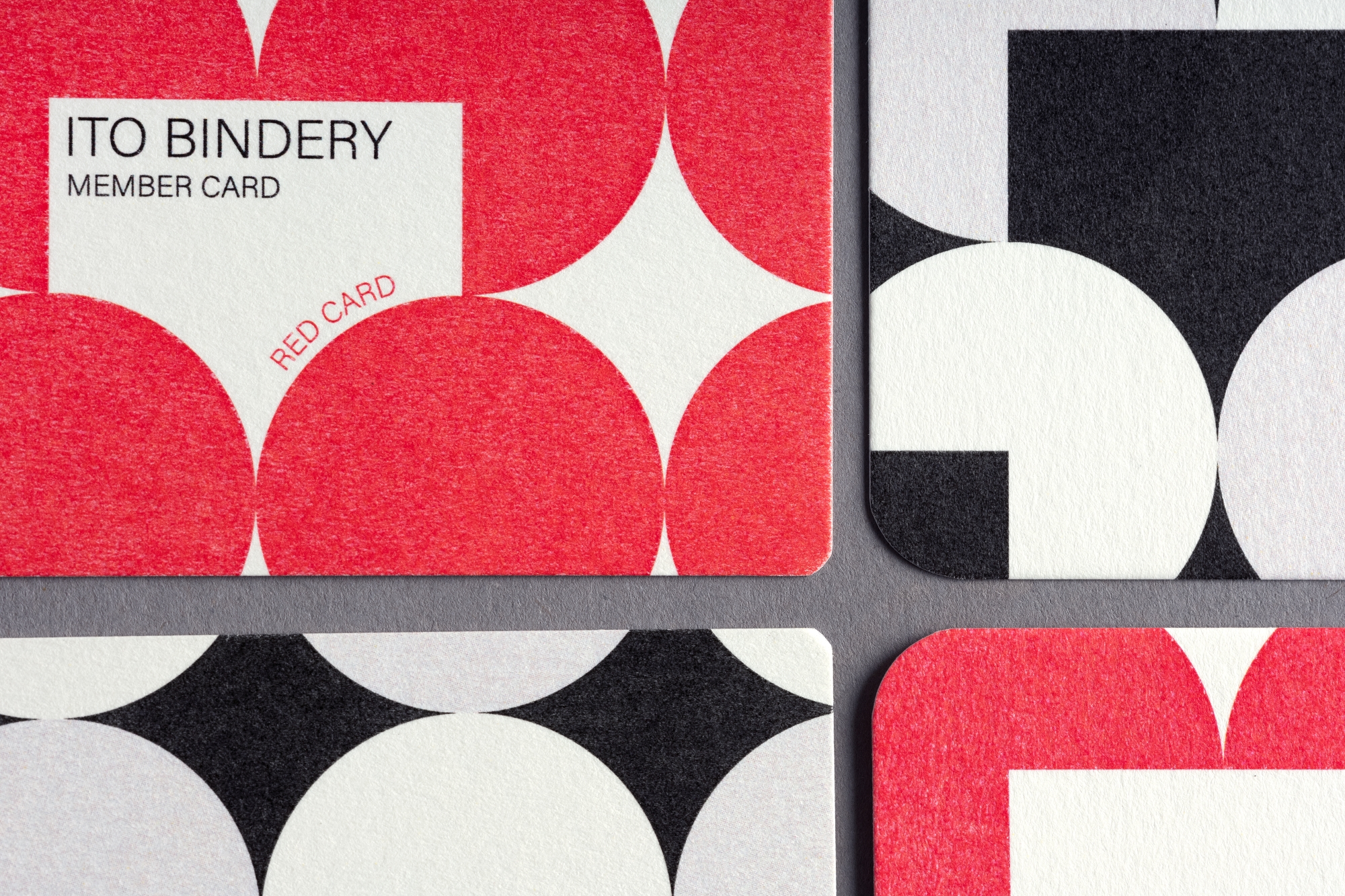

Business Cards

We can cut smaller paper items like business cards, point cards, and even specialized items like perfume testing sheets.

Folding

Mini folding, gate folding, accordion folding, flyer folding, tri-folding, and more (Combination folding, specialized folding)

Tri-folding

The folds are all done in the same direction so they are parallel. We can do both tri-folding and roll folding.

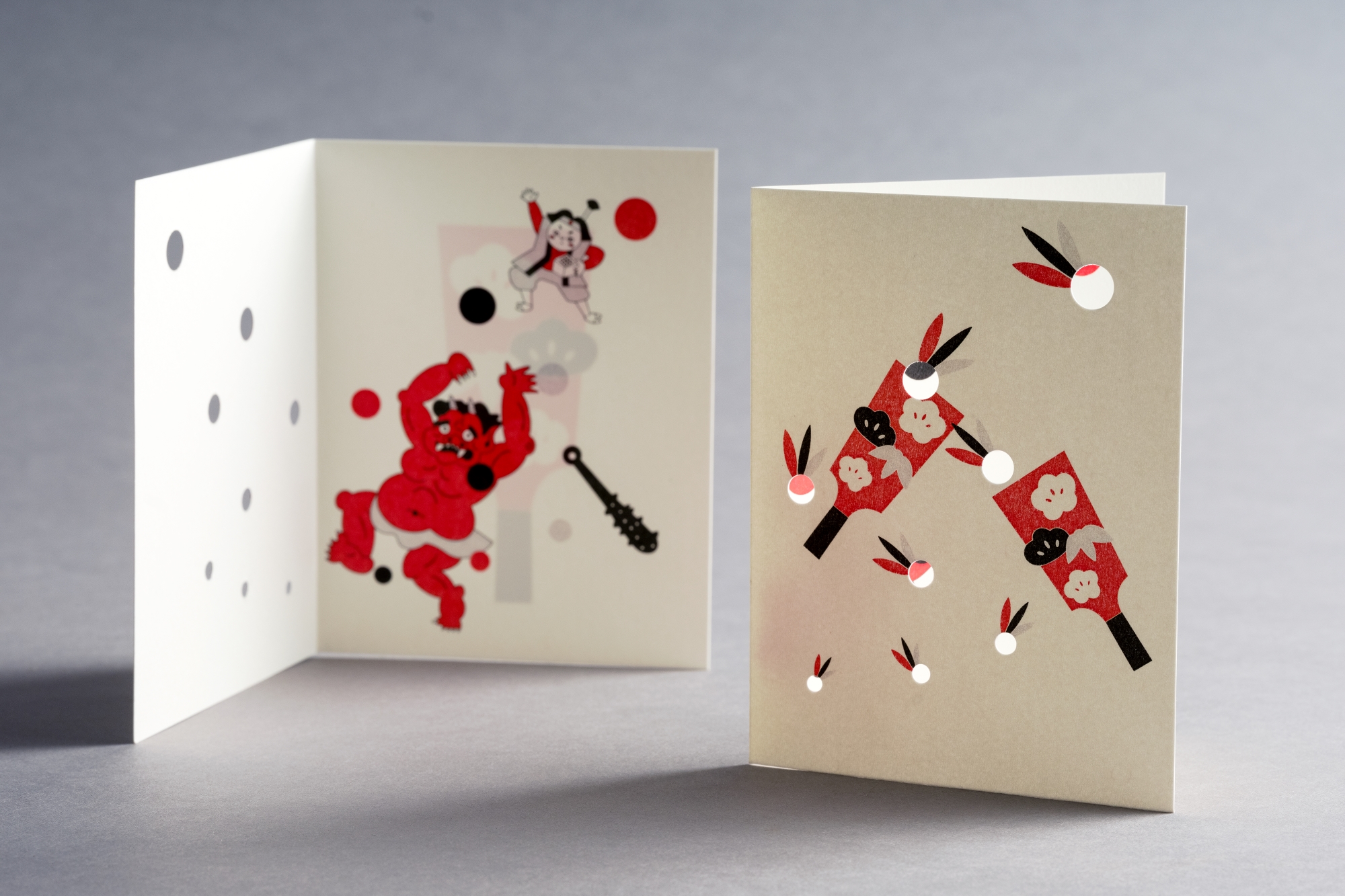

Gate Folding (Double Gate Folding)

Folding the ends of the paper in and then folding the paper in half is what is known as gate folding. This type of fold is often used for store and company leaflets.

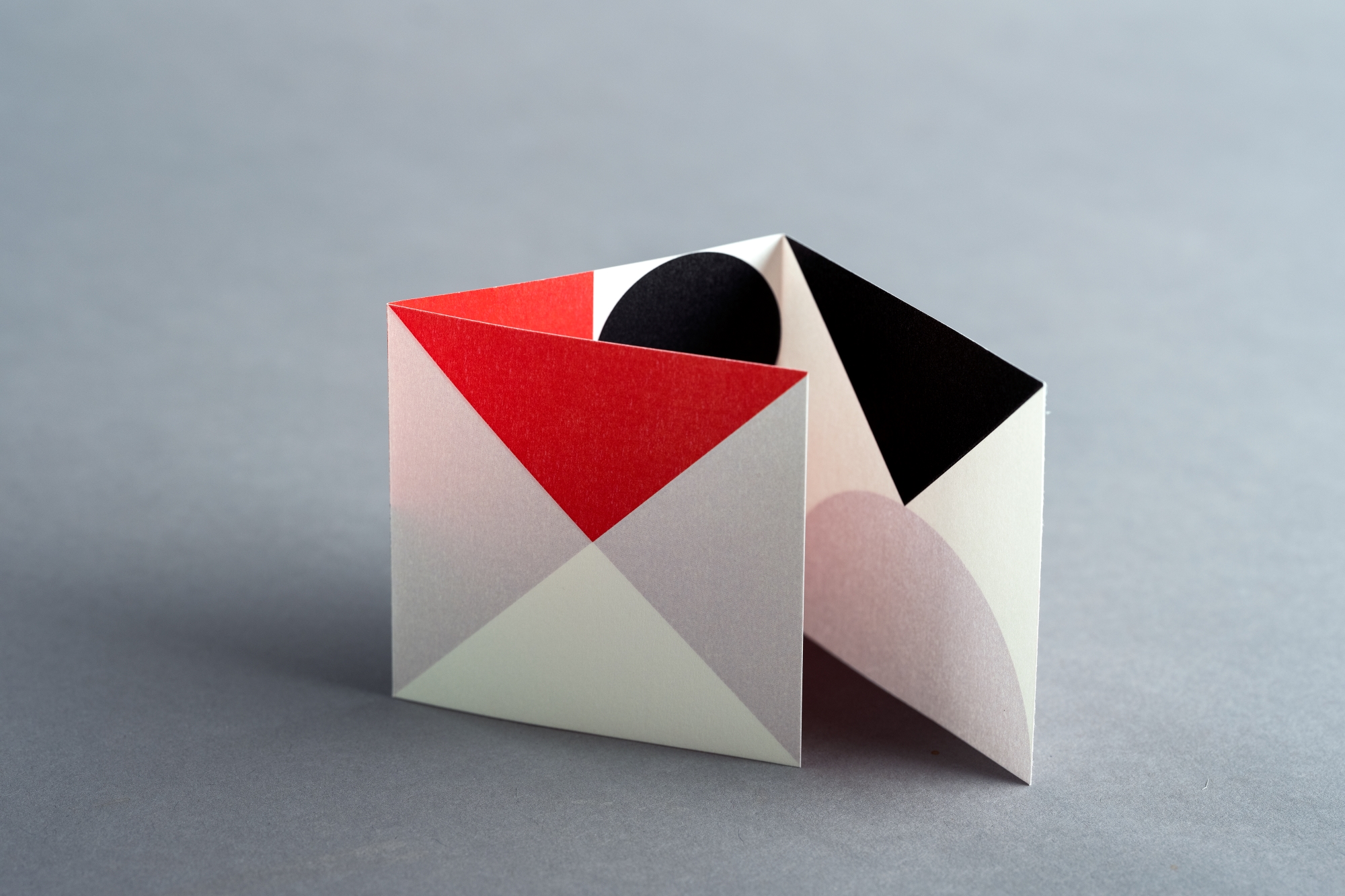

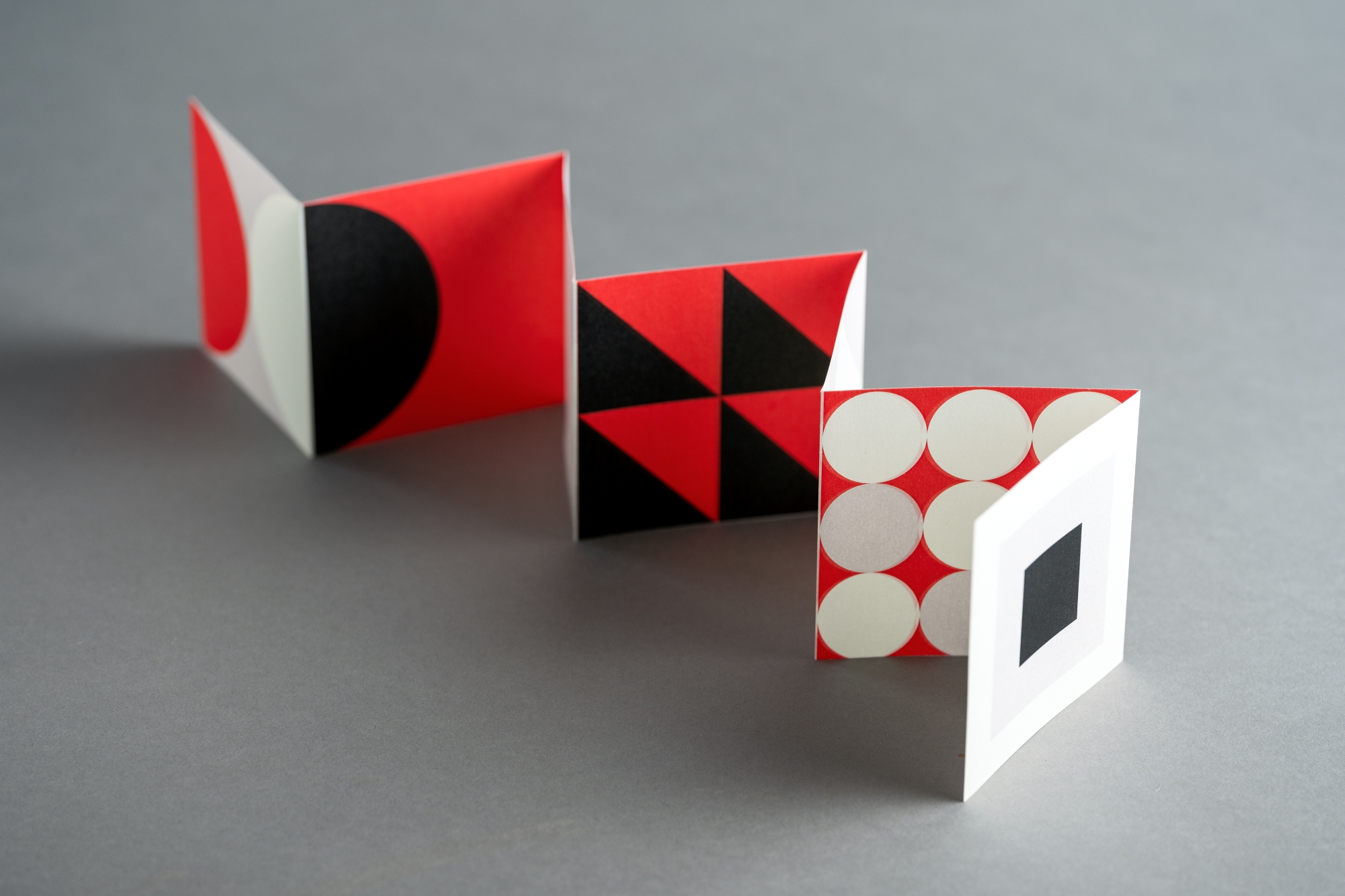

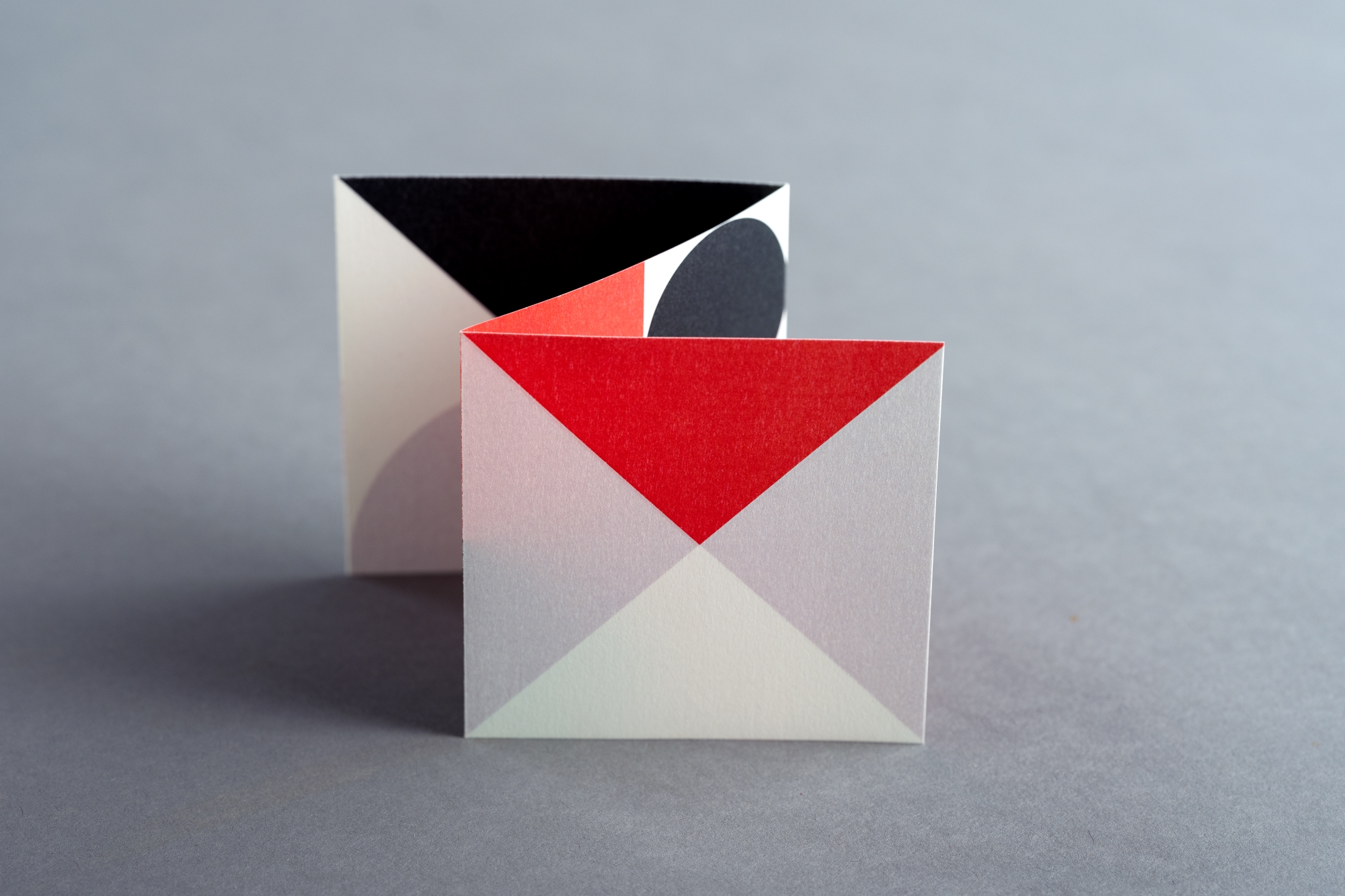

Accordion Folding

When “mountain folds” and “valley folds” are repeated, this zig-zag effect is known as accordion folding (also sometimes called “fan folding”). In Japanese, the number of folds is referred to as the number of “pleats” and “mountains.”

Z-Folding

A type of accordion folding, after just one “mountain fold” and one “valley fold,” the paper will resemble the letter “Z.” Also known as three-panel accordion folding.

Binding

Saddle stitching, collating, inserts, side stitching, burst perfect binding, perfect binding, case binding, and more.

Saddle Stitch Binding

Saddle stitch is a bookbinding method that uses staples in the book’s spine and is suitable for pamphlets and catalogs that range from 8 to 64 pages. This simple design opens easily, and information can be fit across the entire page.

Perfect Binding

Paste is used to solidify the spine, so this durable binding method will help the book last for a long time.

Side Stitch Binding

Often used with order sheets and receipts, this binding method involves binding the paper with staples a few millimeters away from the spine of the item. Our Drawing Pad uses this method so each sheet can be cleanly torn off one by one.

Other Types of Paper Processing

Perforating, scoring, hole drilling, corner rounding, hot foil stamping, cut outs, paste binding, and more.

Hole Punching

We can punch holes in uniform sizes, locations, and pitches that are suitable for loose-leaf paper or planners. We can punch holes from 3mm to 8mm in diameter.

Corning Rounding

We can round corners to R3 and R6. With rounded corners, printed materials look more professional and inviting. This process is perfect for shop cards and pamphlets.

Scoring/Perforating

Scoring is the process of making paper items like shop cards easier to fold. Perforating allows papers like tickets, shopping vouchers, and coupons to be torn easily without the use of scissors.

Hot Foil Stamping

We can do color hot foil stamping in gold, silver, black, and white, as well as translucent stamping, hologram stamping, and debossing. The process allows logos and other personalized touches to stand out, adding a touch of elegance to catalog covers and packaging.

Cut Outs

This process is often used as a “window” on the cover of a book or catalog or to make holders that contain saddle-stitched pamphlets. Our company’s products use this technique for our recycled cardboard packaging.

Paste Binding

Paste binding allows individual sheets to be torn off easily. This process is typically used for order sheets, receipts, memo pads, sticky notes, and more. We use this method in the manufacturing of our Memo Block.